Enterprise Resource Planning (ERP) systems have become a critical backbone for managing a modern supply chain in the manufacturing sector. By seamlessly connecting various business processes from factory floor to inventory to logistics, ERP software helps gain end-to-end visibility across complex manufacturing environments.

Implementing ERP solutions provides tangible improvements in production planning, inventory control, supplier collaboration, and quality management. With valuable data insights, manufacturers can enhance forecast accuracy, optimize capacity planning, accelerate decision-making, and reduce operational costs. Cloud-based ERP systems additionally provide the flexibility to scale production while integrating emerging technologies like IoT and AI.

This article will elaborate on key benefits that manufacturers can achieve by implementing Manufacturing ERP software across the extended supply chain.

Streamlining Supply Chain Processes with an ERP built for the Manufacturing Industry

By centralizing data across the manufacturing network, ERP systems facilitate coordinated planning resulting in streamlined execution. Granular production plans and optimized factory schedules ensure the availability of materials and resources well in advance. This improves productivity by eliminating waste.

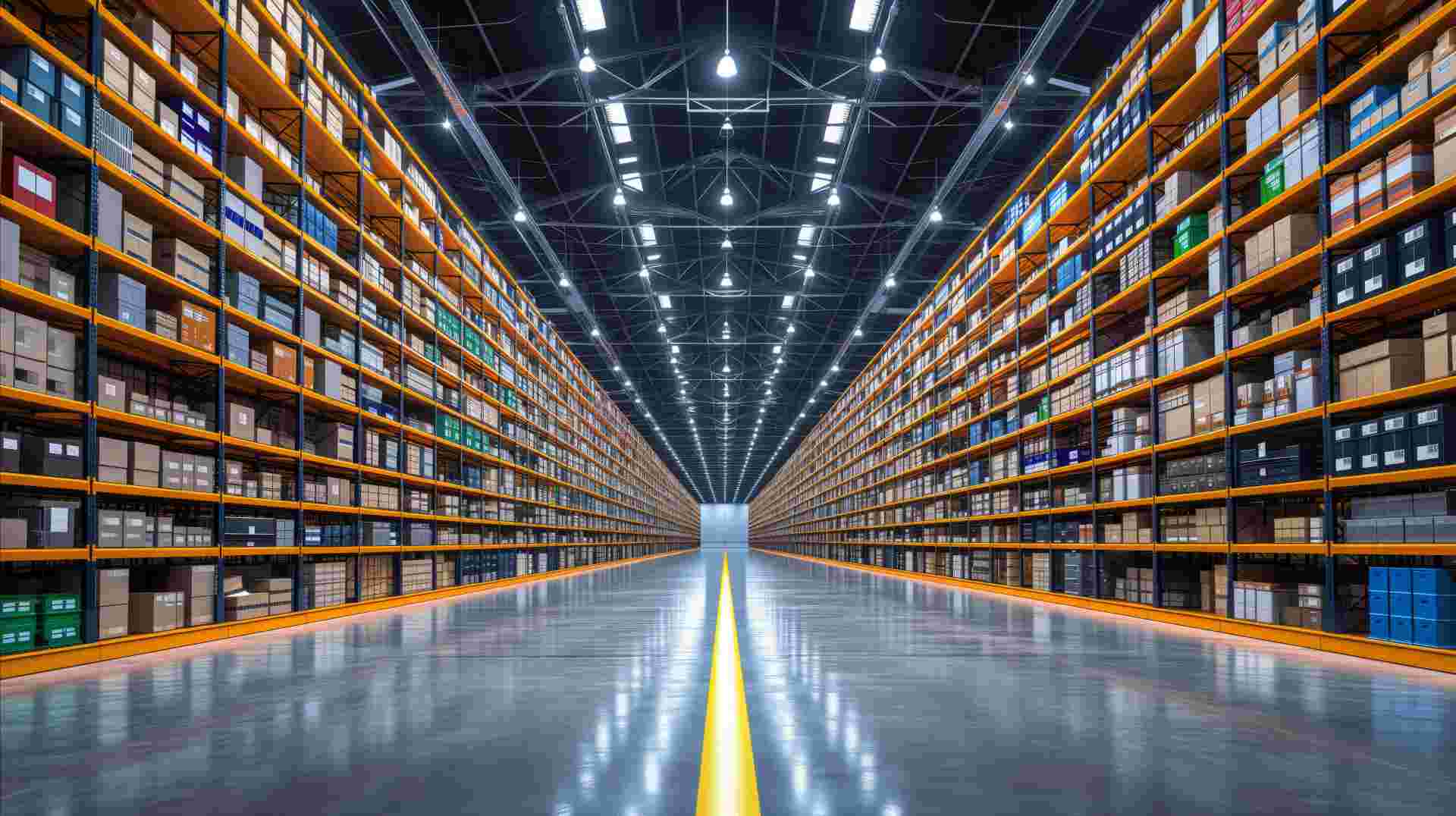

Built-in support for barcode scanning facilitates accuracy in inventory counts while real-time updates reflect precise stock levels across warehouses. Materials Requirements Planning helps trigger automatic purchase orders and transfers based on production plans and inventory policies. This enhances procurement efficiency by removing guesswork while managing working capital requirements.

By connecting sales projections with production capacity, manufacturers can develop realistic demand forecasts at various product hierarchy levels. This alignment helps meet customer expectations while maximizing asset utilization through science-based capacity plans. Order promising logic within ERP provides reliable delivery dates to customers factoring in material availability and production schedules. Advance shipment notifications through ERP further enable supply chain partners to plan warehousing and logistics activities.

Data-driven Decision Making and Visibility

Unified Analytics dashboards in ERP software solutions collate data from shopfloor, warehouses, logistics, and finances to generate actionable insights. Accurate demand projections based on historical patterns, events, promotions, and new product introductions can help production and procurement teams develop robust plans. Executives can track a variety of operational KPIs to accelerate fact-based decision-making aligned with organizational goals.

With end-to-end visibility across a multi-tier supply chain, manufacturers can pinpoint reasons for material shortages or delays and accordingly update production schedules. Compliance with quality guidelines can also be continually monitored to identify areas for improvement. ERP systems thus make the entire manufacturing ecosystem data-driven, agile, and efficient.

Connecting Manufacturing Ecosystem with ERP

Unlike legacy systems, modern ERP platforms provide open APIs and pre-built connectors to securely share critical data with external partners in real time. This enables collaboration with contract manufacturers for better coordination. Suppliers can also view upcoming production plans, manage consigned inventory at manufacturing plants, and ensure timely replenishments.

Vendors-managed inventory (VMI) powered by ERP provides suppliers real-time visibility on consumption across multiple locations while automating purchase order generation based on pre-agreed minimum/maximum levels. Such ERP-enabled inventory optimization minimizes costs associated with expedited shipments and production delays due to stockouts.

With financial data integrated across various business entities, executives can analyze profitability by product lines, channels, and geographic regions using ERP reporting tools. Sales and operations planning (S&OP) also becomes streamlined allowing executives to assess new opportunities and adjust budgets periodically.

Flexibility, Agility, and Future-readiness

Cloud-based ERP solutions provide anywhere, anytime access to authorized users across devices like laptops, tablets, and smartphones. This mobility and flexibility to scale up production is especially relevant for contract manufacturers that need to dynamically balance capacity across multiple customer accounts. With rapid configuration capabilities, cloud ERP also enables the launching of new production sites swiftly by replicating operational blueprints.

While IoT integration allows real-time monitoring of production quality, asset utilization, and energy consumption, ERP systems provide the logical backbone to transform sensor data into contextualized information for factory technicians and managers to act on. Machine learning algorithms applied to aggregated shopfloor data can predict equipment failures, and recommend optimal production batches and schedules, thus enabling smart manufacturing.

With customer expectations evolving rapidly, ERP also plays a pivotal role in achieving omnichannel consistency in B2C operations. By providing a unified data foundation, ERP systems enable the personalization of products based on purchase history and behavior across channels while facilitating order orchestration from anywhere to anywhere.

Overcoming ERP Implementation Challenges

Transitioning from rigid legacy systems to an agile ERP platform poses technological and organizational challenges for manufacturers. While cloud ERP systems reduce hardware investments, manufacturers must evaluate various subscription models based on user roles to ensure ROI. Training resources must focus on simple, intuitive interfaces driving user adoption across roles instead of overwhelming all features.

Change management should focus on employee motivation and clearly communicate the benefits of the new ERP system rather than just imposing it as a mandated technology upgrade. Manufacturers must also assess integration needs with existing PLM, MES, and automation systems so that ERP becomes the “single source of truth” rather than just another siloed application.

While outsourcing the handling of IT infrastructure and upgrades to reliable cloud service providers have become the norm, manufacturers must implement strong access control policies and data encryption measures to minimize risks of security breaches or data leaks especially when collaborating across the external supply chain.

The Intelligent Supply Chain Powered by an ERP built for the Manufacturing Industry

The combinatorial benefits of cloud-native ERP systems and smart manufacturing technologies are a potent catalyst for realizing the vision of intelligent supply chains. With embedded IoT connectivity, ERP software can assimilate data from sensors and automated equipment to gain sharper insights into production costs, quality metrics, and asset health.

Edge computing minimizes network latency allowing real-time alerts and notifications to technicians for quick interventions. With machine learning algorithms assimilating historical patterns, ERP systems can recommend dynamic production schedules, optimal asset maintenance cycles, precise reorder quantities, and other counter-intuitive decisions that maximize ROI.

As ERP platforms evolve into business process hubs enriched by analytical models, conversational interfaces, and expanded collaboration canvas, manufacturers can truly transform into demand-driven, customer-centric, and insights-led smart factories.

ERP Software Selection Considerations

With hundreds of ERP vendors offering multiple deployment and licensing options, selection needs careful evaluation of both technical and commercial parameters depending on manufacturing sub-sector-specific needs. Workload optimization for on-premise servers vs leveraging cloud elasticity is a key technical consideration.

Implementation methodology spanning solution design, data migration, testing, training, and go-live support must incorporate industry best practices to minimize disruptions and accelerate ROI realization. Vendors must clearly specify upgrade cycles, patch management processes, and contingencies for version upgrades or migrations to successor products.

While subscription pricing allows predictable periodic expenses aligned to revenue growth, manufacturers must estimate additional needs for custom development, hardware investments, training, and post-go-live support to accurately project the total cost of ownership. ERP vendors focused on manufacturing verticals and Investments in emerging technologies like IoT, AI, and blockchain signal future-proof implementations central to digital transformation initiatives.

ERP systems will continue to be the core of digital transformation driving intelligent supply chains of the future. With centralized architecture, analytical capabilities, and connectivity, ERP platforms empower manufacturers to achieve new levels of agility, efficiency, and customer-centricity. While technology selection and organizational change management require careful planning, ERP implementation success holds the promise of catapulting manufacturing enterprises to market leadership.

Smart Supply Chains Enabled by Versa Cloud ERP

As discussed above, Robust Enterprise Resource Planning systems like Versa Cloud ERP provide an integrated platform to manage critical business processes spanning factory shopfloors to inventory warehouses and finance functions.

Specifically designed for manufacturers, distributors, and wholesalers, Versa Cloud ERP delivers end-to-end visibility and control across the supply chain ecosystem. Robust modules for production planning, inventory optimization, warehouse management, accounting, and payables ensure streamlined operations and accelerated decision-making.

Seamless collaboration with external partners like suppliers and 3PLs enabled by Versa facilitates vendor-managed inventories, drop shipments, and omnichannel order fulfillment. Compliance with quality, environmental, and regulatory mandates also becomes more efficient through centralized data access.

By harnessing the power of the cloud, mobility, analytics, and emerging technologies, Versa enables the transition to smart, efficient, and customer-centric supply chains. The future-proof solutions portfolio suitably caters to enterprises of varying scale and complexity across industries.

Versa Cloud ERP definitively ticks all checkboxes for a unified manufacturing ERP solution that can rapidly demonstrate ROI while empowering expansion to meet strategic goals. Schedule a free personalized, obligation-free demo today with Versa’s manufacturing consultants to experience the benefits first-hand.

FAQs :

1. How can manufacturing ERP systems help improve overall equipment effectiveness (OEE)?

ERP provides real-time production data to quickly identify bottlenecks causing downtime and quality issues. This enables improving OEE through better asset maintenance, production scheduling, and compliance.

2. What are some key metrics that demonstrate ROI from manufacturing ERP solutions?

Reduced production cycle times, lower inventory costs, improved capacity utilization, decreased quality failures, better order fulfillment rates, and increased on-time shipments are some key metrics.

3. How can ERP systems help manufacturers enable drop shipping to customers?

ERP provides inventory visibility across facilities to fulfill orders through drop shipping. Orders can be electronically shared with suppliers to directly ship to customers.

4. How is blockchain being used in manufacturing ERP systems?

Blockchain facilitates trusted information sharing across the manufacturing ecosystem regarding inventory levels, quality measures, and payment data enabling transparency & provenance.

5. Can ERP software help manufacturers improve their sustainability initiatives?

Yes, ERP provides insights into energy consumption patterns, raw material waste reduction opportunities, and carbon footprint analytics enabling closed-loop circular supply chains.

6. What future capabilities will drive greater ERP adoption in the manufacturing sector?

Technologies like IoT, AI/ML, Digital Twins, and Advanced Analytics will make ERP systems more predictive, prescriptive, and intrinsically intelligent to become true partners.

ERP systems are now fundamental to the efficient management of a modern supply chain in the manufacturing sector. By integrating various business processes, ERP systems streamline operations, enhance visibility, and improve decision-making, making them indispensable tools for manufacturers aiming to stay competitive in today’s market.

Empower your business with the knowledge to navigate the realm of an Integrated ERP solution, specifically tailored to your business needs. Gain insights, streamline processes, and propel your financial management to new heights with this comprehensive guide

With Versa Cloud ERP’s Implementation guide learn how a business can ensure a successful ERP Solution Implementation. Navigate the complexities of implementation with confidence!

Effectively manage your financials, accounting, inventory, production, and warehouse management workflows with our award-winning ERP.

Let Versa Cloud Erp’s do the heavy lifting for you.

[widget id=”custom_html-40″]

[widget id=”custom_html-42″]

[widget id=”custom_html-30″]

Do Business on the Move!

Make your businesses hassle-free and cut the heavyweights sign up for the Versa Cloud ERP today!!

Join our Versa Community and be Future-ready with us.