Will Customer-managed inventory act as the answer to the dilemma of stock management in 2025?

For e-commerce businesses, managing stocks often amounts to a great act of juggling. Too much stock hangs on space and cash, while too little stock annoys consumers and creates losses in sales.

Some businesses seek Vendor-Managed Inventory solutions, yet, at this juncture, they often lose control over their inventory management. But here is a better solution: Customer-Managed Inventory.

CMI is All about Control

With CMI, you hold onto your inventory while enjoying the other benefits of great inventory replenishment. Here’s how it works:

- Real-time framework: You have information on your inventory level in real-time; thus, you know what’s selling and when to restock.

- Improving cash flow: You optimize stock levels and reduce cash tied up in inventory, freeing cash for other parts of the business.

- Less storage cost: CMI assists in avoiding overstocking in the first place, and thus additionally avoids high, unnecessary warehousing costs.

- Faster replenishment: When stock is low, you can quickly replenish it to satisfy customers.

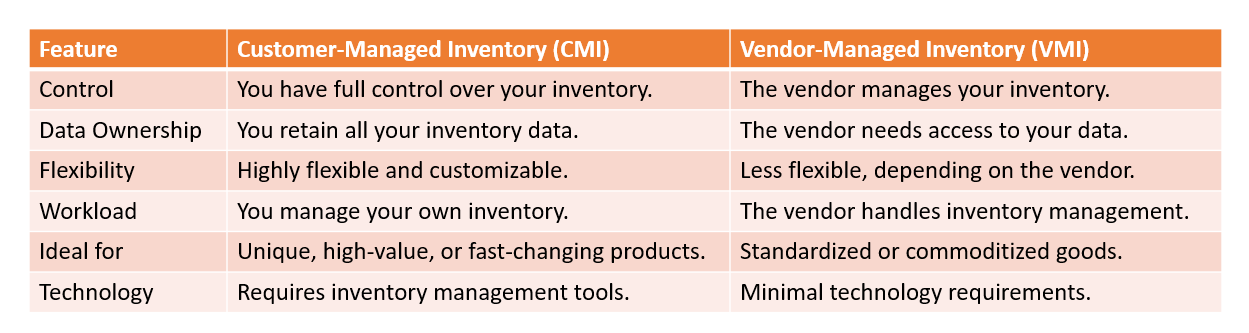

CMI and Vendor-Managed Inventory: The Key Differences

- Control: In CMI, you control your inventory and entirely take the reins on when and how restocking happens.

- Flexibility: CMI provides more flexibility when adapting to demand variations and total market conditions.

- Efficiency: CMI can be more efficient than traditional Vendor-Managed Inventory since you’re not relying on a third party to manage your stock.

By putting CMI into play, customers are empowered to control their inventory levels while improving their cash flow and overall experience.

Key takeaways about CMI:

- Know your inventory: Customers take charge of their inventory tracking by providing real-time data to your systems.

- Fast and Accurate: This means streamlined replenishment and fast, accurate reordering, allowing customers to have the products whenever and wherever they need them.

- Enhanced Control: Customers gain greater control over their inventory and ordering process.

Customer-Managed Inventory: Empowering Customers, Optimizing Efficiency

While there is no denying that business stocks are replenished often for their client, what’s different about customer-managed inventories (CMIs)? The true revolution is imagining that your inventory sits in your customer’s stockroom, and they take the management. But how does it all work?

CMI: A Collaborative Approach

CMI is a partnership between you and the customer in principle, where they are in charge of day-to-day inventory tracking in their warehouse while you handle smooth replenishment. Here is how it works:

- Inventory Setup: Make sure you and your customer develop a thorough list of all required items and the maximum and minimum levels of those items.

- Automated Monitoring: Provide the customer with barcode scanners, RFID trackers, or even weight-sensing bins to take the burden of tracking inventories off their shoulders as much as possible.

- Automatic exchange of data: The customer’s units automatically feed into their computer system. Their computer is directly linked to your inventory management system using EDI technology.

- Automation of replenishment: Once the level of stock drops below a pre-established level, the system automatically issues the order to replenish that stock.

Benefits of CMI:

- Customer Empowerment: Customers have greater control over ensuring they maintain the proper stock levels and reduce all waste.

- Accuracy Improvements: Automated data capture reduces errors and guarantees accurate inventory records.

- Efficiency Improvements: Smoothened processes and automated replenishment would indeed save a lot of time and costs for both you and your customer.

- Collaborative Relationship: CMI enhances working relations between you and your customer, built on trust and shared responsibility.

Customer-Managed Inventory: A Peek Behind the Scenes

So how does a customer-managed inventory (CMI) actually function? It’s like a well-functioning partnership between technology, data, and human input. Here’s a peek at the inner workings:

- Dynamic Inventory Monitoring: Picture your customer’s inventory with some bar code scanners or passive RFID readers in their warehouse. As they receive, consume, or sell products, they simply scan them, and the inventory system is automatically updated with data. This allows for real-time inventory visibility at one’s fingertips.

- Centralized Visibility: The information flows seamlessly into a centralized inventory management system, a command center for your stock. With it, you have a clear view of what’s happening with your inventory at various locations for a more sightly understanding of stock levels.

- Demand Forecasting: Track with trend-ridden analyses, pulling from past sales data and seasonality trends in forecasting future product demand. It would allow you to see what your customers will want and when to proactively replenish to avoid stockouts.

- Automated Replenishment: No more tedious work for someone to do as everything is now at the touch of a button. When stock dips below a specified level, the system automatically triggers a replenishment order, all set to go, depending on the benchmarks that you specified. This enables a seamless supply of goods at all times with minimal interruptions and increased efficiency.

By bringing these components together, CMI empowers companies to optimize their inventory, streamline their operations, and enhance customer relationships.

CMI vs. Traditional Vendor-Managed Inventory (VMI)

Traditional VMI is not like CMI, where the vendor manages inventory. CMI gives control and flexibility back to the customer while still ensuring timely and efficient replenishment.

The implementation of CMI provides customers with the opportunity to take charge of their inventory management as part of a dynamic process while building a stronger and more collaborative relationship.

Customer-managed inventory is a win-win solution for both businesses and customers.

Customer-managed inventory (CMI) is akin to giving your customers the keys to their well-stocked warehouse. They can manage the inventory at their convenience while you manage the replenishment process. It’s a win-win scenario that benefits both the vendor and the customers.

For Vendors:

- Lower Selling Costs: Intend to curb numerous selling trips to customer warehouses to conduct small inventory checks. The CMI automates this for you, thus saving you time and money.

- More Satisfied Customers: Your customers do not complain about overstocking goods or calling for parts that they don’t want because they take control of inventory levels.

- Improved accuracy: Automated processes eliminate manual errors in order entries and allow more accurate real-time inventories.

- Increased revenue: CMI makes it easier for customers to produce orders, thus leading to more frequent and larger orders and increasing sales volume and revenue.

For Customers:

- Greater control: Customers are provided with full control over their inventories, including what to order, when to order, and how much to have on hand.

- More flexibility: CMI enables customers to scan and keep inventory at their convenience and seamlessly fits into their current work processes.

- Improved accuracy: Scanning reduces mistakes and thus ensures inventory data accuracy to enable better decision-making.

- Multi-location support: CMI is workable across numerous places of stocking, starting from warehouses to retail showrooms, providing a comprehensive view of the inventory.

- Lower cost: Now customers can optimize stock levels, ultimately reducing waste, reducing carrying costs.

- Stronger Partnerships: CMI fosters a collaborative relationship between vendors and customers, built on trust and shared responsibility.

CMI vs. VMI: Choosing the Right Inventory Management Strategy:

Choosing between customer-managed inventory (CMI) and vendor-managed inventory (VMI) can be tricky. It’s like choosing between two different types of vehicles – each has its own advantages and best-use cases.

Here’s a quick comparison to help you decide:

Who Benefits Most from CMI?

- Luxury and high-value brands: CMI provides the control and flexibility needed to manage these specialized items.

- Direct-to-consumer (DTC) brands: CMI allows for greater control over the customer experience and inventory flow.

- E-commerce startups and niche brands: CMI offers a cost-effective way to manage inventory and adapt to changing demand.

Who Stands to Gain Most from VMI?

- Bulk wholesalers: VMI can improve inventory management for big volume options of standardized products.

- Retail chain: VMI can speed up replenishments and lighten the load for store staff.

- Companies with inventory on consignment: VMI gives the vendor power to manage inventory held at the customer’s location.

Customer-Managed Inventory-Game-Changer for E-Commerce Success

Inventory management is not a luxury but a dire necessity in modern-day e-commerce competition. CMI gives businesses power over stock and makes the running of things smooth while enhancing customer experience.

Here’s how CMI benefits e-commerce businesses:

-

Cost-saving and efficiency:

- Lower holding costs: CMI prevents companies from excessive stocking by synchronizing inventory to real-time demand.

- No vendor fees: Bid goodbye to hefty vendor-managed inventory arrangements.

- Flexibility: Allow for rapid adjustments in order to respond to demand changes while avoiding needless costs.

-

Better inventory control:

- Real-time visibility: Have a clear view of stock and values at any given time.

- Dynamic adjustments: Quickly respond to demand changes and reallocate stock as needed.

- Greater control: Make decisions regarding one’s inventory without relying on third-party forecasts.

-

Faster replenishment:

- Scattered inventory: Have an inventory location all over the coastline and replenish goods in a much shorter time for the benefit of less shipping distance.

- Take away the lead time: No more waiting for processing and shipping of merchandise to the inventory.

-

Better customer relations:

- Stock availability: Keep products always stocked, making customers happy.

- Fully satisfied delivery: Option for expedited shipping to meet customer expectations for speed and convenience.

- Improved satisfaction: Keep up the customer loyalty flow by providing a seamless and dependable shopping experience.

By deploying CMI in your eCommerce firm, you enjoy every competitive advantage you can lay your hands on, whilst also creating efficient operations and enhanced customer satisfaction.

Ultimately, the best choice depends on your specific business needs, resources, and priorities. Consider factors like the type of products you sell, your relationship with your customers, and your internal capabilities when making your decision.

A Guide to Customer-Managed Inventory: Definitive Step for E-business Success

CMIs can change the way you run e-commerce, but that will take proper planning and the right tools to implement successfully. Here is your guide:

1. Select the Right Technology Partner:

CMI needs a strong inventory management system, competent for providing real-time visibility and control. Search for a partner like Versa Cloud ERP, which would provide the capability to track inventories across numerous sites efficiently and automate crucial processes.

2. Enable Your Team:

Train your staff on how to undertake basic tasks of using the inventory management system and how to handle stock properly. This prevents errors, ensures data accuracy, and streamlines any operation.

3. Partner with Your Fulfillment Partner:

An effective fulfillment partner, Versa Cloud ERP, can provide the structure and technology to carry out your CMI strategy, inclusive of its reliable expertise in optimizing the ABCs of inventory storage, distribution, and replenishment.

4. Automation and Analytics:

Automate the reordering and stock management processes and other tasks, then track inventory on an inventory analytics dashboard to identify demand trends, understand inventory patterns, and drive decisions using data.

By following these measures, you can successfully implement CMI, optimize your inventory management, and transform your e-commerce to make it more effective, profitable, and cost-effective to the customers.

So you wonder if CMI is right for the business.

- To improve order accuracy.

- Lower inventory costs.

- Empowering customers.

- Streamline sales processes.

- Enhance customer relationships.

If yes, then CMI is the right way to go.

CMI will bring your business to higher operational efficiency, collaboration, and customer satisfaction, ensuring both your and your customers’ growth and success.

To learn more about how Versa Cloud ERP can optimize your inventory management, reduce your costs, and boost your bottom line.

Take the First Step Towards Transformation

Email: sales@versaclouderp.com

Email: sales@versaclouderp.com

Instant Demo Registration: Demo Registration Link

Instant Demo Registration: Demo Registration Link

By taking a collaborative approach, Businesses can build a culture of continuous improvement and achieve sustainable operational efficiency without overwhelming your team or disrupting your business.

Don’t let inventory challenges hold your business back. Discover the Versa Cloud ERP advantage today.

Effectively manage your financials, multiple channel inventory, and production workflows with our award-winning ERP.

Let Versa Cloud ERP do the heavy lifting for you.

Do Business on the Move!

Make your businesses hassle-free and cut the heavyweights sign up for the Versa Cloud ERP today!!

Join our Versa Community and be Future-ready with us.

[widget id=”custom_html-20″]