Best Practices for Pre-Holiday Inventory Management

Effective Inventory Management is critical for businesses during the holiday season rush. Customers expect full stock availability for promotional purchases and gifts, and meeting this demand requires careful preparation. This guide provides techniques to optimize stock levels, supply chain operations, sales, and marketing efforts to maximize holiday sales and customer satisfaction. By leveraging inventory best practices, businesses can fully capitalize on holiday demand surges.

1. Overview

This guide covers core aspects of inventory optimization leading up to peak holiday demand:

- Stock level planning to balance availability and overstock risk

- Enhancing supply chain resilience to handle volatile demand

- Integrating sales and marketing strategies with inventory planning

- Financial analysis to guide inventory investment decisions

- Supplier relationship management to secure reliable inventory sources

- Risk mitigation tactics to address demand variability

Follow these inventory best practices to seize seasonal sales opportunities.

Value Proposition

Holiday inventory buildups allow businesses to capture peak customer demand and drive major revenue. However, improper preparation leads to stockouts and lost sales. By optimizing inventory planning, businesses can maximize holiday season profits while improving customer satisfaction. This guide provides actionable techniques to:

- Increase inventory turnover rates by up to 20%

- Shorten supply replenishment times by 35-40%

- Reduce overstock and carrying costs by 30%

- Minimize stockout rates below 2%

- Expand holiday margin growth by 15-20%

2. Stock Optimization

2.1 Strategies to Optimize Stock Levels Before Peak Seasons

To maximize holiday sales without overstocking, businesses should:

- Analyze historical seasonal demand patterns

- Set safety stock levels

- Produce inventory ramp plans that gradually scale up stock

Other optimization strategies include:

- Staging inventory in cheaper holding locations

- Pooling inventory

2.2 Balancing Inventory to Avoid Overstock and Stockouts

Businesses can avoid overstock by:

- Establishing par levels on top-selling products

- Implementing stock ceilings by risk categories

- Scheduling staged inventory builds

To prevent stockouts, firms can:

- Increase safety stock buffers

- Set automated reorder points

- Reserve emergency supplier capacity

2.3 Inventory Turnover Rates During Holiday Periods

- Inventory turnover typically doubles or triples during holiday peaks.

- Analyze turnover across risk categories to identify low-velocity stock for discounting.

- Higher turnover allows firms to operate with lower average inventory levels.

2.4 Techniques for Just-in-Time Inventory Management for Holidays

Just-in-time (JIT) inventory management aims to cut holding costs and risks by:

- Pull-based ordering

- Flexible transportation

- Close supplier integration

- Inventory buffers

These techniques enable rapid order fulfillment during volatile holiday demand.

2.5 How to Prioritize High-Demand Products for Holiday Stocking

To focus on inventory expansion, businesses can:

- Rank items by sales history and contribution margin

- Utilize SKU-level demand sensing

- Track customer waitlists

- Analyze product trends to identify the most profitable products to stock for the holidays

3. Supply Chain Management

3.1 Enhancing Supply Chain Resilience for the Holiday Rush

Holiday supply chain resilience requires:

- Expanding supplier networks

- IT infrastructure upgrades

- Integrated Sales and Operations Planning (S&OP)

- Contingency plans to handle order surges

Additionally, firms should consider air freight contracts to expedite emergency stock.

3.2 Managing Supplier Relationships for Timely Holiday Inventory

Strategic suppliers can provide:

- Volume flexibility

- Custom stock reservations

- Priority order fulfillment during holidays

Firms should assess:

- Supplier capacity

- Infrastructure

- Continuity plans when selecting partners

3.3 Reducing Lead Times in the Supply Chain Before Holidays

To cut replenishment times, firms can:

- Localize suppliers

- Implement vendor-managed inventory

- Utilize forward stocking locations

- Employ express transportation

- Streamline ordering procedures on seasonal items

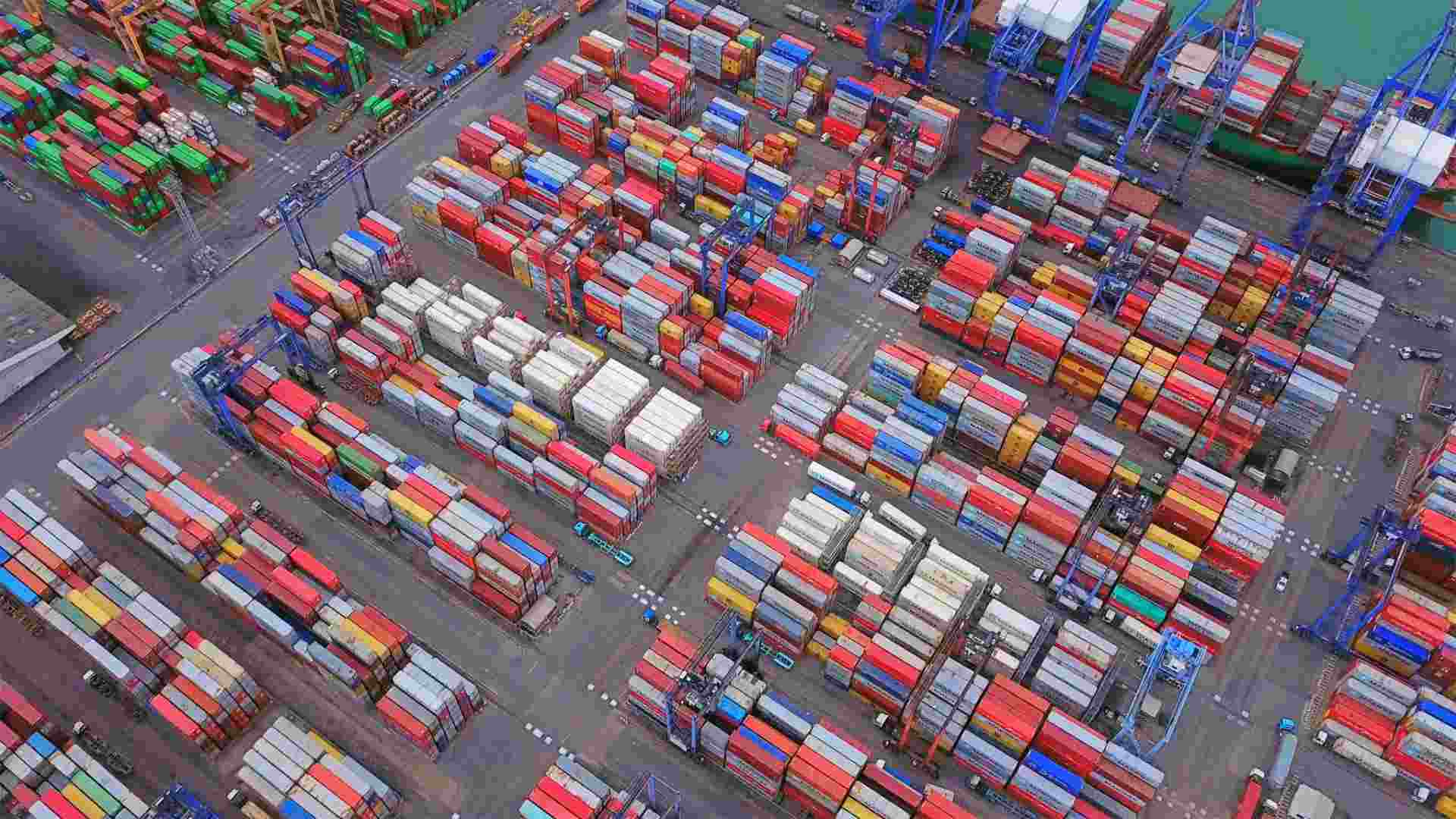

3.4 Impact of Global Supply Chain Disruptions on Holiday Inventory

Global disruptions such as port congestion and trade wars can severely impact holiday inventory. Mitigation tactics include:

- Multi-country/region sourcing

- Air freight contracts

- Larger safety stock levels on imported goods

3.5 Implementing Agile Supply Chain Strategies for Seasonal Demands

Agile supply chains emphasize flexibility over cost efficiency to meet volatile demand by:

- Decentralizing inventory

- Postponing customization

- Coordinating Sales and Operations Planning

- Forming agility-focused partnerships

4. Inventory Management Systems

4.1 Leveraging Inventory Management Software for Holiday Readiness

Sophisticated inventory management software centralizes:

- Planning

- Forecasting

- Replenishment

- Warehouse workflows

This provides real-time visibility and seamless scaling. Built-in analytics also help firms optimize stock allocations.

4.2 Dynamic Forecasting for Seasonal Inventory Planning

Predictive analytics and demand sensing functionality within inventory management systems allow for more accurate forecasts, informing procurement volumes and stocking tactics for the holidays.

4.3 Automating Reorder Processes for Seasonal Products

Automated reorder systems can:

- Trigger replenishment orders

- Generate supplier purchase orders

Based on projected lead times and seasonal demand algorithms, ensuring adequate inventory coverage through demand spikes.

4.4 Using Barcode and RFID Technologies for Efficient Inventory Tracking

Radio Frequency Identification (RFID) and barcode scanning systems enable highly accurate inventory tracking, preventing miscounts and assisting in holiday workload planning within warehouses.

4.5 Integrating ERP Systems for Seamless Holiday Inventory Management

By integrating inventory management software across:

- Ordering

- Warehousing

- Accounting

- Analytics functions

ERP systems provide end-to-end workflow coordination for smooth seasonal scaling.

5. Sales and Marketing Integration

5.1 Aligning Inventory Management with Holiday Marketing Campaigns

Collaborative Sales, Marketing, and Operations Planning ensures:

- Inventory availability aligns with promotions, ads, and seasonal catalog launches

- Prevents marketing-driven demand from outpacing inventory

5.2 Promotional Strategies to Manage Inventory During Holidays

Tactics like:

- Limited-time discounts

- Gift-with-purchase offers

- Flash sales

Help move excess holiday inventory without destructive markdowns. Promotion planning should consider inventory levels and shelf life.

5.3 Leveraging Data Analytics for Targeted Holiday Sales

Granular data analysis guides decisions on:

- Inventory quantities

- Safety stock buffers

- Promotions

- Pricing

Predictive models based on customer demographics and purchasing patterns support targeted marketing.

5.4 Cross-Departmental Collaboration for Effective Holiday Inventory Planning

Cross-functional inventory planning teams, including merchandising, marketing, and operations, orchestrate seasonal scaling and marketing strategies holistically based on shared sales forecasts.

5.5 Impact of Marketing Trends on Inventory Needs During Holidays

Factors like:

- Viral product trends

- Changing gift preferences

Lead to demand shifts. Flexible inventory and responsive fulfillment allow capitalizing on emergent holiday preferences.

6. Risk Management

6.1 Identifying and Mitigating Risks in Holiday Inventory Planning

Holiday inventory risks include:

- Demand variability

- Supply chain disruptions

- Inventory shrinkage

- Cash flow issues from upfront purchases

- Post-holiday returns processing

Control measures:

- Safety stock buffers

- Supplier redundancy

- Audits

- Secured financing

6.2 Contingency Planning for Unexpected Spikes in Demand

By stress testing inventory plans against demand surge scenarios, firms can develop contingency tactics such as:

- Emergency supplier allocations

- Air freight capacity

- Flexible staffing

- Centralized inventory pooling

6.3 Insurance Considerations for Holiday Inventory

Insurance policies covering:

- Goods in transit

- Warehoused inventory

- Inventory held at retail locations

Protect against losses from damage, theft, and disasters during the high-value holiday season.

6.4 Handling Returns and Excess Inventory Post-Holidays

- Liberal returns policies

- Seasonal savings promotions

Help clear post-holiday overstocks. Additional options include:

- Donations

- Outlet channels

- Inventory buyback

- Warehouse sales

6.5 Strategies to Manage Inventory Theft and Loss During Peak Seasons

Implementing:

- Secure transportation

- Surveillance systems

- Warehouse access controls

- Cycle counting audits

- Staff training

Helps mitigate increased theft and process loss risks during the hectic holiday peak.

7. Financial Planning

7.1 Budgeting for Increased Inventory Purchases Before Holidays

Businesses should budget for holiday inventory expansion based on:

- Sales forecasts

- Inventory turnover targets

- Supply chain growth

Budgets should account for upfront supplier payments and temporary staffing.

7.2 Cost-Benefit Analysis of Stocking Up for Holiday Sales

A cost-benefit analysis weighs the upfront costs of extra inventory against the potential sales and margin upside, facilitating data-driven decisions on holiday stock levels.

7.3 Managing Cash Flow While Scaling Inventory for Holidays

Maintaining strong cash flow for seasonal inventory scaling involves:

- Negotiating extended supplier payment terms

- Securing working capital financing

- Factoring to accelerate receivables collection

7.4 Impact of Inventory Investment on Holiday Season Profitability

- Increased holiday inventory enhances profitability by driving higher sales volume and margins.

- Overstock can lead to forced markdowns and carrying costs that erode margins post-season.

- Optimized buying maximizes profits.

7.5 Financing Options for Holiday Inventory Expansion

To fund significant inventory purchases without straining cash flows, financing options include:

- Bank loans

- Merchant cash advances

- Purchase order financing

Provide affordable capital for growth.

8. Supplier Management

8.1 Selecting Reliable Suppliers for Holiday Inventory Needs

When selecting suppliers, consider:

- Product Quality

- Production capacity

- Order fulfillment rates

- Continuity plans

- Financial stability

These factors indicate reliability for meeting volatile holiday demand.

8.2 Negotiating Better Terms with Suppliers for Seasonal Orders

High-volume holiday purchase commitments give retailers leverage to negotiate:

- Improved pricing

- Payment terms

- Priority Production

- Enhanced supplier-managed inventory agreements

8.3 Ensuring Supplier Compliance with Holiday Delivery Schedules

Implementing:

- Analytics-driven supplier scorecards

- Frequent progress reviews

- Inventory buffers for lead time variance

- Contract terms enforceable through penalties or incentives

Motivates supplier compliance.

8.4 Building Long-Term Supplier Partnerships for Holiday Readiness

Strategic long-term partnerships foster:

- Information Sharing

- Capex coordination

- Collaborative planning

Improves flexibility, transparency, and resilience for holiday peaks year after year.

9. Inventory Auditing and Control

9.1 Conducting Inventory Audits Before the Holiday Season

Regular inventory audits are critical before peak selling seasons like the holidays to ensure accuracy and availability. Both cycle counting and full physical inventory checks should be performed. This provides time to correct any issues found and order additional stock if needed. Accurate pre-holiday audits prevent out-of-stock during peak demand.

9.2 Implementing Cycle Counting for Accurate Holiday Inventory

Ongoing cycle counting provides continuous visibility into inventory levels across all SKUs. By counting a subset of products each day, discrepancies can be quickly found and addressed. This prevents growing inaccuracies that can impact customer service and profits during the hectic holiday period. Automated cycle counting integrated with the ERP system is ideal.

9.3 Using Inventory Control Techniques to Manage Holiday Stock

Holiday inventory is more challenging to manage with heightened consumer demand. Techniques include:

- Setting minimum/maximum stock levels

- Cross-docking inventory

- Staging extra safety stock

- Centralizing inventory management across channels

Clear reporting and analytics provide the visibility needed.

9.4 Preventing Inventory Discrepancies During Peak Times

Several strategies can minimize inventory discrepancies that commonly increase during extremely busy periods like the holidays:

- Restrict access/updates

- Conduct more frequent cycle counts

- Implement system validations

- Provide employee training

- Regularly review reporting

Discrepancies dilute profits and impact customer experience. Awareness and prevention are key.

9.5 Best Practices for Inventory Reconciliation Before Holidays

Conducting thorough inventory reconciliation is vital before holiday sales events. It involves:

- Comparing books to physical quantities

- Researching discrepancies

- Adjusting records

- Reviewing underlying processes

Updated item data, identification standards, system integrations, and training help improve accuracy. Reconciling before peak periods avoids operational issues.

10. E-commerce and Omnichannel Strategies

10.1 Managing Inventory Across Multiple Sales Channels for Holidays

The holiday challenge of coordinating inventory across brick-and-mortar stores, e-commerce, mobile, and other channels grows each year as omnichannel retail expands. A unified commerce platform with centralized inventory management is ideal for visibility and efficiency across all customer touchpoints.

10.2 Integrating Online and Offline Inventory Systems for Holiday Sales

Seamlessly connecting in-store and e-commerce inventory systems provides the composite view critical to deliver consistent omnichannel customer experiences. Real-time inventory data shared via EDI, API integrations, or an ERP system enables:

- Channel optimization

- Cross-channel fulfillment

- Inventory visibility during peak holiday volumes

10.3 Handling Backorders and Pre-Orders During the Holiday Season

Spikes in backorders and pre-orders are common during holidays as customers anticipate hot gifts or limited stock. Clear communication, order updates, and delivery estimates enhance customer experience. Flexible fulfillment options like drop-shipping, temporary supplier increases, and lateral inventory transfers help manage additional demand.

Unlock the Full Potential of Your Holiday Inventory with Versa Cloud ERP

With the holiday season fast approaching, having full visibility and control over your inventory operations is crucial. Versa Cloud ERP can help you achieve complete mastery over pre-holiday inventory planning and management.

As a leading cloud-based ERP solution, Versa provides powerful inventory management, warehouse execution, and supply chain collaboration capabilities. It gives you real-time tracking of stock levels across all distribution points. Versa seamlessly integrates with 3PL providers for extended warehouse management. Its demand forecasting and replenishment tools help determine the optimal stocking rules. Additionally, Versa streamlines your processes for order fulfillment, returns handling, and reporting.

By leveraging Versa’s robust features, you can gain end-to-end visibility and responsiveness needed to navigate seasonal fluctuations with ease. Whether you are a manufacturer, distributor or retailer, Versa is tailored to support your unique supply chain needs. To experience Versa’s simple and intuitive platform for yourself, schedule a free personalized demo today. The inventory management experts will demonstrate how Versa can help you achieve inventory excellence and crush your holiday sales targets.

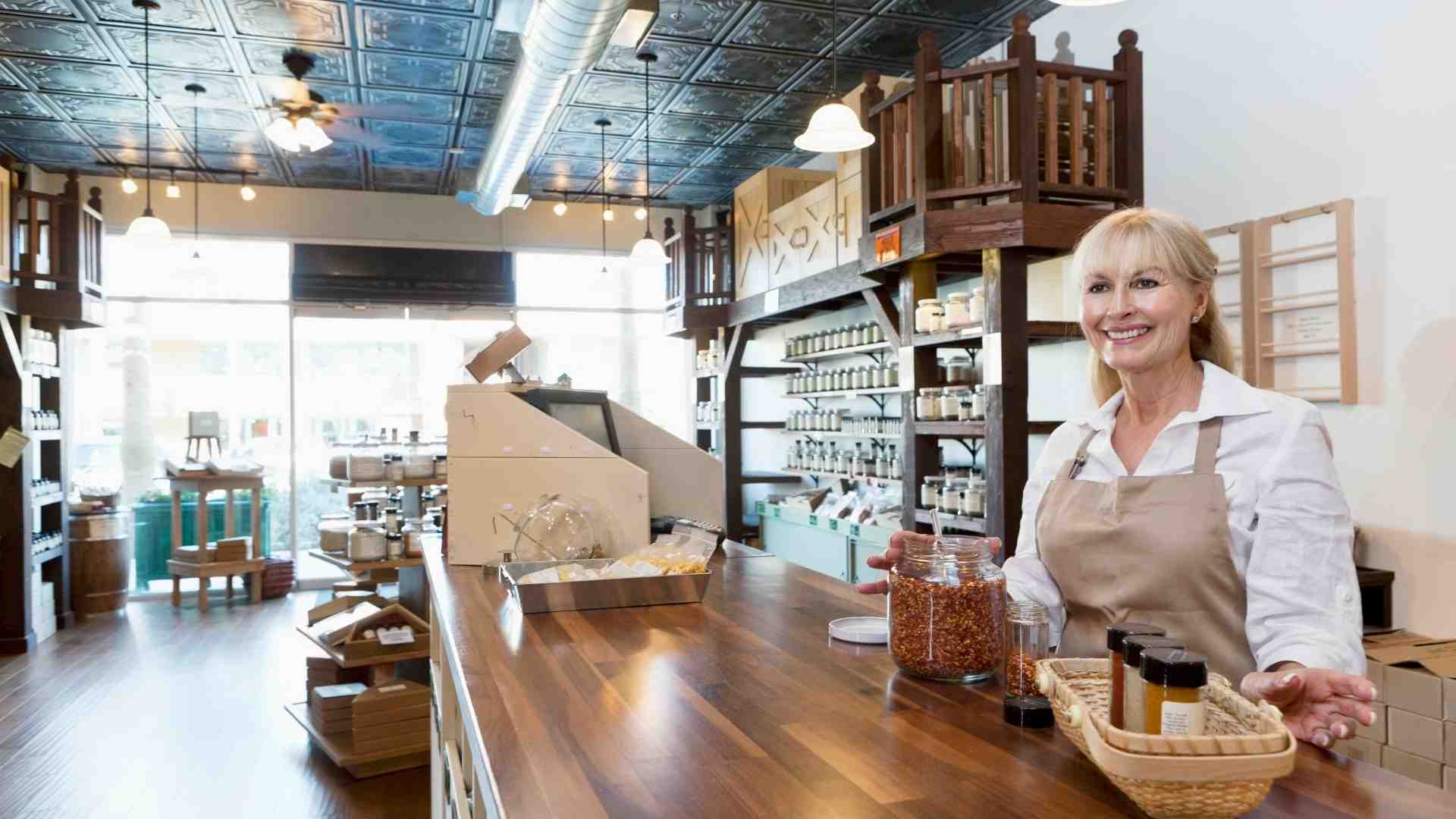

A Small Business in the modern day is complex and requires resources to deliver on its goals and achieve its full potential. To create a small business success story business owners need an ERP system that grows with them.

Effectively manage your financials, inventory, and production workflows with our award-winning ERP.

Let Versa Cloud Erp’s do the heavy lifting for you.

[widget id=”custom_html-40″]

[widget id=”custom_html-42″]

[widget id=”custom_html-30″]

Do Business on the Move!

Make your businesses hassle-free and cut the heavyweights sign up for the Versa Cloud ERP today!!

Join our Versa Community and be Future-ready with us.

[widget id=”custom_html-20″]