Procure-to-Pay Transformation

Procure-to-pay (P2P) refers to the end-to-end process of procuring goods and services, receiving them, and making payments to suppliers. For modern businesses, transforming their P2P operations through digitization and automation delivers immense value. This comprehensive guide will explore what P2P encompasses, its importance, and how technology-enabled P2P solutions generate significant cost savings, efficiencies, and risk reduction.

What is Procure-to-Pay and Why Does it Matter?

Procure-to-pay begins with identifying a need for goods or services and selecting an appropriate supplier. It involves placing purchase orders, receiving and inspecting deliveries, verifying invoices, approving payments, and reconciling accounts payable.

For organizations still relying on paper-based workflows, P2P is often riddled with inefficiencies – lost documents, duplication of efforts, maverick spending, and limited visibility into spend. Modernizing P2P through digital tools provides complete spend visibility, enhances compliance, reduces costs, and allows teams to focus on more strategic work.

This article will provide readers with a deeper understanding of P2P and how transforming these processes through technology delivers quantifiable business benefits.

The Phases of the Procure-to-Pay Process

Procure-to-pay consists of the following key phases:

Needs Identification

The first step is identifying a need for procurement – whether it’s raw materials for manufacturing, office supplies, or a new software solution. Having clear spending policies and approvals in place ensures only necessary purchases are made.

Supplier Selection and Ordering

Once a procurement need is established, potential suppliers are evaluated based on pricing, quality, reliability, and other factors. Quotes may be solicited to aid the supplier selection process. Approved purchases are formalized through purchase orders.

Goods Receipt and Inspection

Upon delivery of goods or services, the quantity, quality, and accuracy of the order must be verified before acceptance. Discrepancies are addressed with the supplier immediately.

Invoice Reconciliation and Verification

The supplier invoice should match the initial purchase order and delivery receipt details. Invoice validation procedures prevent duplicate payments and billing errors.

Payment

Finally, upon invoice verification, payments are made to the supplier in accordance with negotiated terms.

Transitioning from Manual to Automated P2P

For decades, organizations have relied on manual methods to handle P2P workflows. This involves paper purchase requisitions, phone and fax orders, spreadsheets to track spending, and invoices processed by hand.

Manual P2P leads to limited visibility, inefficient processes, and a higher potential for errors. Research indicates it costs organizations $12 to $20 to process a single invoice manually.

Conversely, automated P2P systems provide:

- Online catalogs and purchase requisitions to enable informed procurement

- Digital purchase orders and fast supplier integration

- Electronic invoices and automated matching to orders

- Rules-based approval workflows and exception handling

- Real-time reporting on spending analytics

Automating previously manual steps facilitates information flow between procurement, suppliers, and finance teams. This level of digital connectivity unlocks significant benefits which the next section will explore in detail.

The Strategic Value of Modern Procure-to-Pay Solutions

Transitioning from paper-based P2P to automated digital workflows provides these key advantages:

1. Increased Visibility and Control Over Spend

Automated P2P platforms provide real-time insights into budgets, expenditures, supplier payments, and more. This spend visibility enables data-driven decisions on procurement strategy.

2. Improved Compliance and Risk Reduction

Digital P2P includes built-in validations and alerts to enforce procurement policies and procedures. This minimizes non-compliant spending while audit trails improve accountability.

3. Higher Productivity Across Teams

When manual tasks are reduced through automation, procurement, finance, and other groups can refocus their time on value-adding activities.

4. Cost Savings From Process Efficiencies

Studies show optimized P2P results in up to 30% reduction in procurement costs. Digital workflows eliminate paper, minimize errors, improve information access, and speed up transactions.

Let’s look at some of the specific areas where costs are reduced:

- Lower transaction costs: Automated ordering, invoicing, and payment cuts per transaction fees.

- Reduced maverick spend: With better policy control and fewer ad hoc purchases.

- Lower administrative costs: As manual paperwork and validation steps are reduced.

- Improved supplier discounts: Accelerated invoice processing enables early payments to suppliers in return for discounts.

- Decreased procurement expenses: Data-driven insights help consolidate suppliers and negotiate better contracts.

These quantitative cost reductions are complemented by other qualitative benefits like improving employee engagement as teams transition to more strategic tasks.

Embedding Risk Management Best Practices Into P2P

While automated P2P provides many benefits, it also calls for updated risk mitigation strategies. Organizations should ensure proper controls are in place for:

- Fraud prevention – Using technologies like AI to detect duplicate invoices or identify suspicious transactions.

- Regulatory compliance – Having checks in place to enforce trade, tax, and other regulations.

- Cybersecurity – Securing P2P platforms through authentication, encryption, and access controls.

- Supplier risk – Conducting ongoing assessments of supplier quality, performance, and financial stability.

- Business continuity – Building resilience for events like natural disasters that could impact P2P operations.

By proactively identifying and planning for risks, organizations can reap the rewards of automated P2P without exposing themselves to potential pitfalls.

Integrating Procure-to-Pay with ERP Systems

A critical step in P2P transformation is integrating the new digital workflows with the organization’s existing Enterprise Resource Planning (ERP) system like Versa Cloud ERP, SAP, or Microsoft Dynamics.

Tight integration between P2P and ERP provides:

- A unified data environment – Avoiding silos and enabling real-time exchange of procurement, inventory, and payment information.

- Improved efficiency – Preventing duplicate data entry across disconnected systems.

- Enhanced compliance – Embedding control checkpoints between connected systems.

- Greater analytics – Combining insights from the ERP and P2P systems.

While P2P and ERP integration involves technical challenges, the benefits make it well worthwhile. Some best practices include defining clear integration requirements up front, thoroughly testing connectivity, and having change management processes to support integration.

Overcoming Top Procurement Challenges with ERP

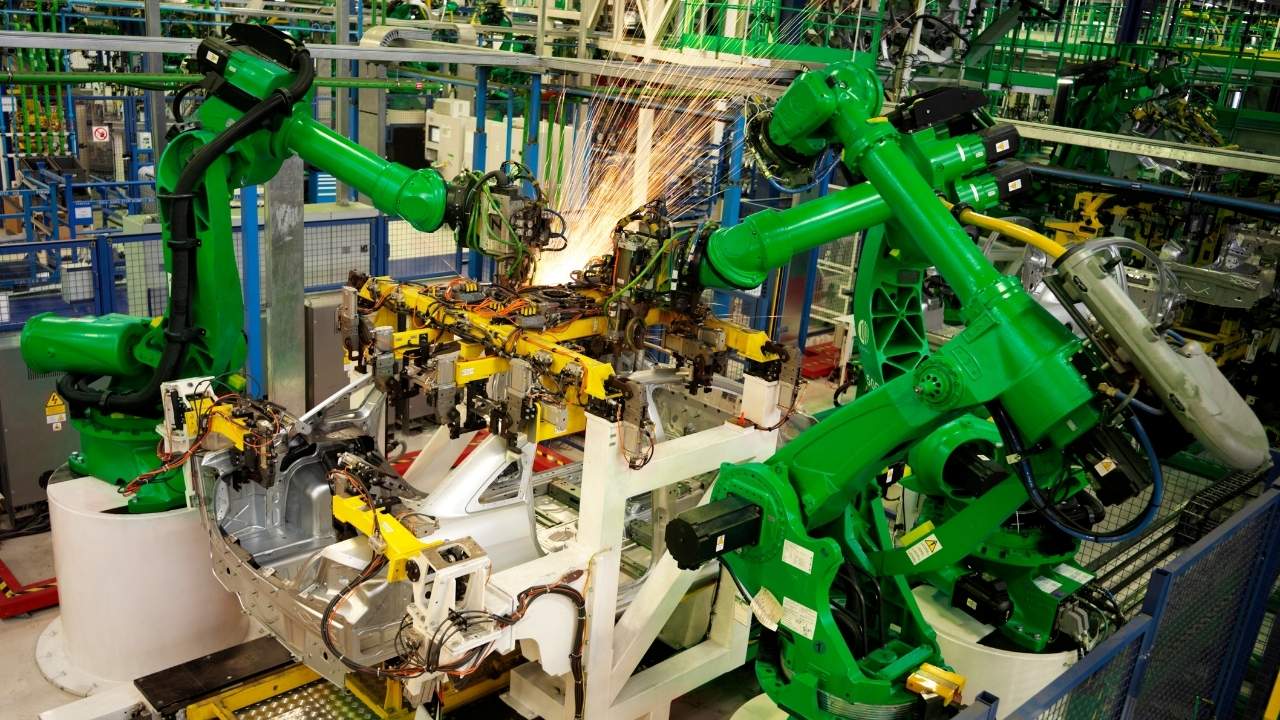

Manual procurement processes in manufacturing often lead to excess spending, difficulty tracking orders, inaccurate inventory, invoicing errors, and weak supplier relationships. ERP software provides solutions to these problems.

Automated Purchase Requisitions and Approvals

Instead of using paper forms, online requisitions and workflow approvals in ERP systems accelerate the ordering process. Configurable approval rules ensure proper oversight over spending.

By streamlining the requisition process with automated workflows, ERP systems enable manufacturing companies to order materials and supplies more quickly. Online forms replace slow paper-based requisitions. Routing requisitions through the right approval channels is simplified through ERP approval workflows that can be configured to match a company’s policies. For example, purchases above a certain amount may require manager or executive sign-off.

With automated approvals, requisitions are not delayed waiting for authorizers to manually sign paper forms. However, proper spending oversight is maintained through the configurable approval rules.

Real-Time Inventory Tracking

Advanced ERP solutions give real-time visibility into inventory quantities across multiple warehouse locations. This helps purchasers know exactly when to reorder materials or parts to prevent shortages.

In addition, automated reorder point alerts in ERP inventory modules can help optimize stock levels. By setting minimum reorder points in the system, purchase orders can be triggered automatically when a material or part stock drops below a preset level.

Real-time inventory tracking prevents production delays from material shortages. It also reduces excess inventory build-up across facilities.

Accounts Payable Invoice Automation

ERP systems expedite invoice processing by automatically matching invoices to corresponding purchase orders and goods receipts. This prevents duplicate or inaccurate payments.

Invoice automation features like duplicate checking and 3-way matching of invoices to orders and receipts result in faster payments to suppliers with fewer errors.

Strategic Sourcing and Supplier Management

The comprehensive data in ERP systems aids strategic sourcing analysis to reduce material and part costs. Supplier portals allow digital collaboration and order fulfillment. Analytics provides insights to strengthen supplier performance management.

By leveraging ERP data for spend analysis, manufacturers can identify opportunities for pooling demand across business units and aggregating purchases from fewer suppliers to get volume discounts. Supplier portals enable digital order placement and fulfillment, improving accuracy and speed. Analytics tools help track and improve supplier key performance metrics like on-time delivery rates.

Cutting Costs Through ERP Procurement Automation

Research shows manufacturers can cut procurement costs by 20-30% by implementing ERP systems. These savings come from:

- Lower material costs via sourcing analytics and demand aggregation

- Reduced maverick and excess spending with better spend control

- Faster procurement cycles through workflow automation

- Minimized overpayments from invoice automation

- Improved supplier order accuracy through digital collaboration

In addition, ERP systems drive working capital improvements through optimized inventory management and early payment discounts from suppliers.

Enabling Procurement Agility with ERP

Volatile demand, supply disruptions, and changing markets require manufacturing companies to be agile. ERP systems deliver procurement agility through:

- Real-time data for faster response to changes

- Flexible workflows to adapt processes

- Mobile access empowering purchasers with on-the-go capabilities

- Supplier integration enabling digital collaboration

By automating repetitive manual tasks, ERP systems free up procurement teams to focus on more strategic initiatives.

In summary, by transforming procurement operations with process automation and digital capabilities, ERP software enables manufacturing enterprises to reduce costs, improve agility, and strengthen their supply chains.

The Link Between Procure-to-Pay and Supplier Relationships

Beyond cost and efficiency gains, modern P2P also provides an opportunity to improve supplier relationships.

Digitizing and automating P2P allows buyers to:

- Give suppliers real-time visibility into purchase orders, deliveries, invoices, and payments.

- Provide on-time payments to suppliers by accelerating invoice processing.

- Use P2P data for collaborative planning with suppliers on inventory and logistics.

- Embed electronic communication tools across the P2P platform.

These capabilities help strengthen supplier partnerships, enabling both sides to become more responsive and agile.

Realizing the Full Potential of Procure-to-Pay with Versa Cloud ERP

As this guide has shown, procurement is no longer a siloed back-office function. Optimized P2P facilitated by digital tools and automation delivers far-reaching benefits across the enterprise – from spend visibility and control to reduced costs, improved compliance, and closer supplier collaboration.

Versa Cloud ERP provides manufacturing enterprises with a powerful integrated suite that automates and optimizes procurement processes. By streamlining purchasing workflows, Versa helps drive significant cost reduction and efficiency gains in procurement operations.

With Versa’s real-time inventory tracking, automated PO and invoice processing, and data analytics capabilities, manufacturers can gain deep visibility and control over spending. This minimizes maverick and excess purchasing while enabling sourcing optimizations.

Seamless integrations between procurement, accounting, warehouse management, and manufacturing modules ensure smooth end-to-end P2P workflows. Versa’s ability to connect external supplier networks and 3PLs provides flexibility in engaging business partners.

As a cloud-based solution, Versa Cloud ERP delivers rapid implementation, ease of upgrades, and accessibility from any location and device. This empowers procurement agility to adapt to changing market dynamics.

With decades of experience serving manufacturers, Versa Cloud ERP stands out as a complete, user-friendly, and affordable ERP system. To experience the benefits of Versa’s procurement automation capabilities, contact us today to schedule a free personalized demo.

A Small Business in the modern day is complex and requires resources to deliver on its goals and achieve its full potential. To create a small business success story business owners need an ERP system that grows with them.

Effectively manage your financials, inventory, and production workflows with our award-winning ERP.

Let Versa Cloud Erp’s do the heavy lifting for you.

[widget id=”custom_html-40″]

[widget id=”custom_html-42″]

[widget id=”custom_html-30″]

Do Business on the Move!

Make your businesses hassle-free and cut the heavyweights sign up for the Versa Cloud ERP today!!

Join our Versa Community and be Future-ready with us.

[widget id=”custom_html-20″]